WE DESIGN AND MANUFACTURE THE HEAT EXCHANGER YOU NEED.

- PROFESSIONAL EXPERIENCES IN MECHANICAL DESIGN, THERMAL DESIGN, & FABRICATION OF HEAT EXCHANGERS.

- ADVANCED MECHANICAL & THERMAL DESIGN SOFTWARES ARE USED TO SUPPORT OUR DESIGN.

* MFG. & DESIGN CODE : API / TEMA / ASME

FINNED TUBE TYPE HEAT EXCHANGERS USED AS HEATER, COOLER, ECONOMIZER, etc.

AIR COOLED HEAT EXCHANGER (ACHE)

THE ACHE IS A DEVICE FOR REJECTING HEAT FROM A FLUID DIRECTLY TO AMBIENT AIR.

INSTALLATION OF AIR COOLED HEAT EXCHANGER

INSTALLATION OF AIR COOLED HEAT EXCHANGER

WASTE GAS PREHEATER

WASTE GAS PREHEATER

AIR COOLER FOR OIL COOLING

AIR COOLER FOR OIL COOLING

AIR COOLER FOR OIL COOLING

AIR COOLER FOR OIL COOLING

STEAM / HOT OIL / THERMAL FLUID AIR HEATER

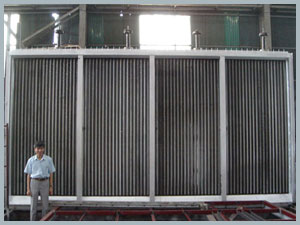

STEAM AIR PREHEATERS PROJECT IN KRABI POWER PLANT OF ELECTRICITY AUTHORITY OF THAILAND (EGAT)

STEAM AIR PREHEATERS PROJECT IN KRABI POWER PLANT OF ELECTRICITY AUTHORITY OF THAILAND (EGAT)

* DESIGN CONDITION OF STEAM AIR PREHEATER:

- HEAT DUTY: 8,712,577.19 KCAL/HR

- DESIGN PRESSURE: 20 BARG

- DESIGN TEMPERATURE: 250°C

- PRESSURE DROP ALLOWED: 122 mm H2O

- PRESSURE TEST: 30 BARG

STEAM AIR HEATER

STEAM AIR HEATER

THERMAL OIL/ AIR HEATER FOR STARCH DRYER (3,500,000 KCAL/HR)

THERMAL OIL/ AIR HEATER FOR STARCH DRYER (3,500,000 KCAL/HR)

ECONOMIZER / HEAT RECOVERY COIL

FLUE GAS ECONOMIZER

FLUE GAS ECONOMIZER

FLUE GAS ECONOMIZER

FLUE GAS ECONOMIZER

ECONOMIZER FOR BOILER

ECONOMIZER FOR BOILER